-Support to assist client's to design the products

-Rich experience of evaluate different design to help client to optimize the design and save the cost.

-OEM & ODM are supported

-Rich experience of project management with a strong track record of turning customers’ innovative concept designs into product

-Single and Multi-cavity is available.

Main information of molding:

| Mould material |

LKM2083,LKM2344,8406, 8407, S136, LKM2767 718H,NAK80,SKD61,H13 etc. |

| Mould base |

LKM, ML, HASCO etc. |

| Mould life |

40,0000 or as per request |

| Plastic material |

PVC,PS,PP,PC,ABS,TPR,PET,POM,PMMA etc. any plastic |

| Cavity |

single or multiple cavity |

| Doff way |

Auto by ejectors, Doff plates, Air valves etc |

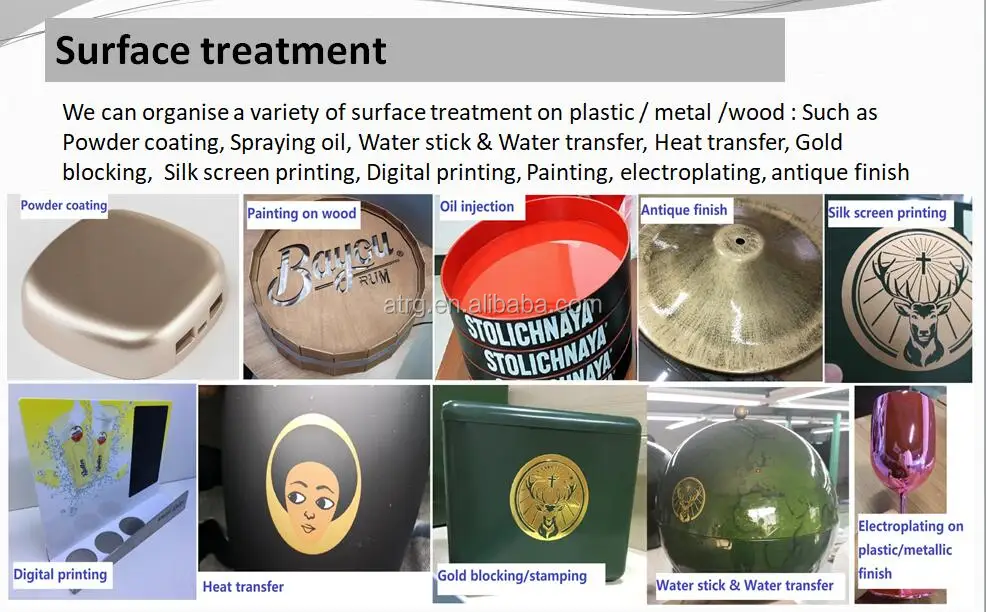

| Surface treatment |

Polish, etch |

| Processing |

CNC, High speed carve, E.D.M, Wire cut, Drill, Injection etc. |

| Hardness after quenching |

HRC52-54 |

| Application |

For medical device, household appliance, automobile spare parts, electronics etc. |

| Lead time |

4-8weeks |

| Packing |

Plywood box+pallet |

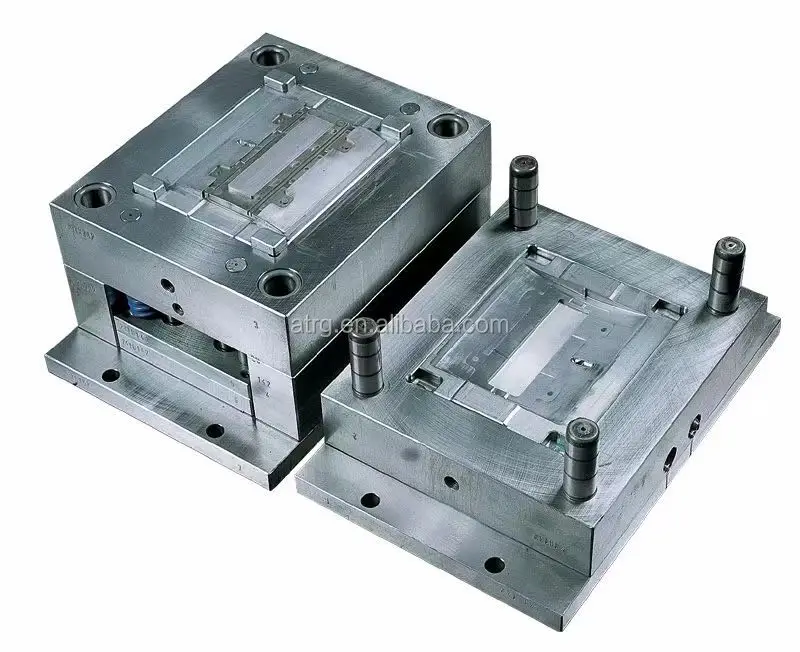

Reference photos of molding:

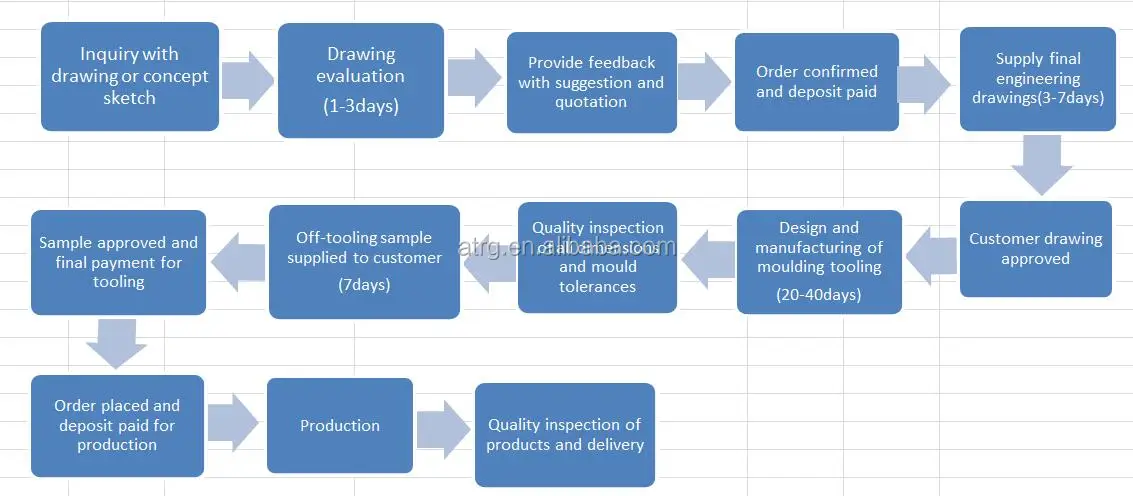

Project flow chart:

General information of factory:

|

General information of mould factory

|

Founded in 2010, over 8000 square meters , over 100 workers&staffs, 41sets machines & equipment for molding & production, over 20sets device for QC check. |

| Staffs |

35workers for injection molding, 74 workers for production, including 11 engineers & technicians |

| Machines&equipment |

Plastic injection machine:18sets;

Molding equipment&machine(CNC, carved & milling machine, grinding machine, spark machine) 18sets;

Auxiliary equipment(central frozen water system, air compressor, material grinding machine etc.): 5sets

|

| Production capacity for plastic products production |

Daily production 1000-5000pcs (based on the size of the product) |

| Maximum molding size |

8T, max.size 1.3m, each weight of plastic product 2.6kg

|

Why choose us:

-Over 20 years professional experience of injection mouldingbusiness

-Over 10 years injection mouldingfactories in different scale for option, we will assign proper scale factory for your project accordingly .

-Our background and multilingual skills enable us to straddle and understand client’s requirements and expectations, as well as different cultural perspectives for providing effective executions to ensure progress and schedules proceed according to agreed quality and time targets.

-Local support in Australia

-Team knows plastic materials very well.

-Eco-friendly plastic materials. ( ROHS, REACH, CA65, Food grade)

-Variety of surface treatment can be achieved.

-Large volume injection production .

-Strong lab service support to help you understand the standard in different fields well and also avoid the potential risk.

Please feel free to contact us if any further question or requirement.

Email:

Phone & Wechat: +86